THE CHIP 1 EDGE

Discover Our Key Differentiators

Cost Savings and Franchise Solutions

Chip 1 offers electronic components from franchise lines and open market, ensuring reliable availability and cost efficiency for seamless electronic sourcing

Excess Inventory Management

Chip 1 helps companies turn surplus inventory into a profitable revenue stream with expert solutions, optimizing inventory management and boosting ROI

Shortage & Obsolescence Management

Chip 1 ensures seamless access to obsolete parts, proactively overcoming sourcing challenges to keep your supply chain running smoothly

Chip1

Laboratories

At Chip 1, every part undergoes rigorous testing in our global QC labs, ensuring transparency and accountability for reliable component sourcing

Data Intelligence Services

MyChip1 is the ultimate one-stop platform, offering comprehensive part data, real-time market visibility, and pricing insights—empowering faster, and smarter sourcing decisions

De-Risking Supply Chain Strategies

Chip 1 identifies at-risk components, optimizes allocations, and tailors inventory plans to prevent shortages and obsolescence, ensuring a disruption-proof supply chain

Internal Risk Management Solutions

Chip 1’s solution streamlines operations, reduces risk, and enhances competitiveness with intuitive, proactive, and seamlessly integrated component management for a more efficient supply chain

Transforming Electronic

Components Distribution

with solutions to improve

sourcing efficiency, market

visibility, and cost savings

500+

Employees Globally1Mn+

Orders Shipped to Customers$100Mn+

Value of Parts in StockPRODUCTS

Active Components

Integrated Circuits | Transistors | MOSFET | Diodes | Resistors

Passive Components

Capacitors | Resistors | Transformers | Inductors

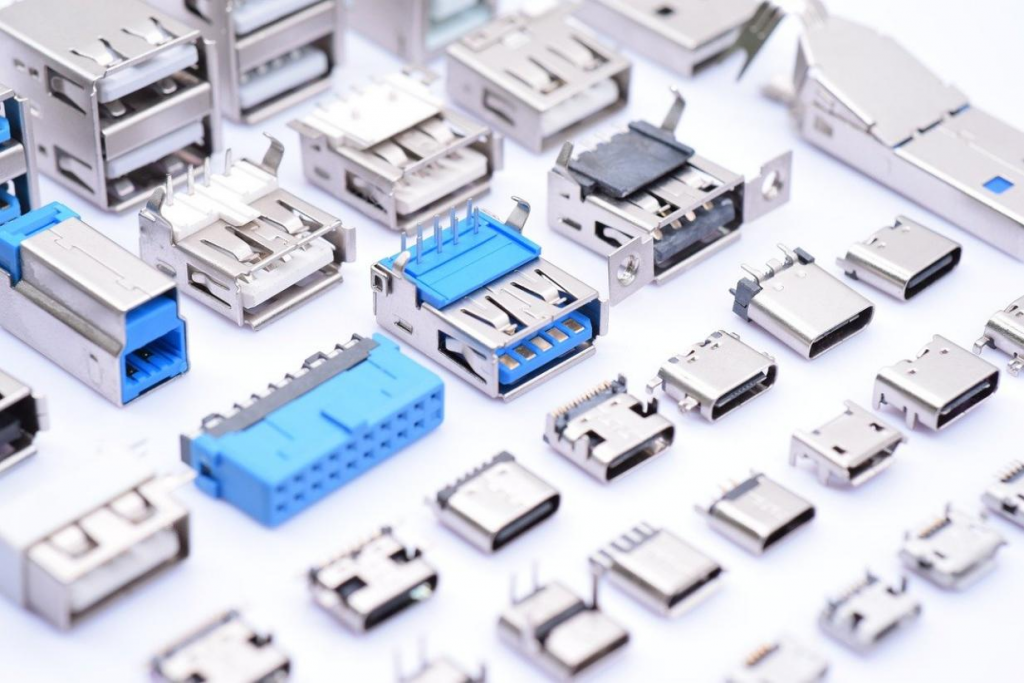

Electro-Mechanical

Cables | Switches | Terminals | Connectors Resonators

System Level Components

CPU (Mobile, Desktop, Server) | GPU | Memory, Modules | Storage (HDD, SSD)Welcome to the Future of Sourcing!

Introducing MyChip1 - the ultimate platform for supply chain professionals, providing an all-in-one solution to optimize electronic component sourcing. MyChip1 delivers:

- Comprehensive Part-Level Data: Access parametric data, datasheets, and PCNs in one place

- Real-Time Market Visibility: Stay updated with franchise and open market availability

- Up-to-the-Minute Pricing: Make faster, informed decisions with real-time pricing insights

By consolidating these powerful features into a seamless platform, MyChip1 enables you to optimize workflows, reduce supply chain risks, and make more efficient sourcing decisions